COMPANY

Finish the product without excess or deficiency.

This is the condition of "manufacturing".

Action policy

1. Instead of making excuses that we can't do, we think of ways we can.

2. we always think and act.

3. we pursue speed in every situation.

4. we are thoroughly committed to information sharing.

5. We value the circle of the company and cooperate with each other.

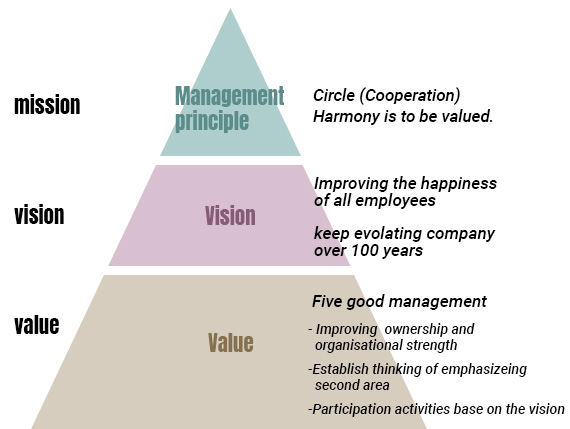

01. Mission

Sum [unity cooperation]

Respect with harmony

Corporate Philosophy "Mission / Significance of Existence"

All employees should cooperate with each other to respect the circle and share information thoroughly.

02. Vision

Improving the happiness of all employees,

Make our company an evolving company that has continued for over 100 years

Corporate Vision "Long-term Aim"

All employees and people involved

Being a company that is constantly evolving.

*The people involved are employees and their families, outside employees (suppliers / partner companies) and their families, current and future customers, local residents, investors, and other related parties.

03. Value

5 good management

Values / Action Guidelines As "values that should be cherished"

We will realize the "correct management that realizes happiness" of "5 good" that Taisho Optical thinks from "3 good" of Omi merchants.

- Awareness that you are directly related / Strengthen organizational strength.

- Establishing thinking that emphasizes the second area.

- Participation activities centered on the vision.

Taisho Optical Philosophy

Taisho Optical's Philosophy

The organization consists of three levels: "meaning of existence = mission", "aim = vision", and "values / action guidelines equal values".

After acting based on value, we aim for a long-term vision and realize our mission. Philosophy is a company philosophy, but it is also a place to go back when you are at a loss about solving problems within an organization.

We will make this axis an important OS for each employee and for the entire organization. In addition, it was the founder, Chairman Atsushi Naito, who created this basic idea. Since its founding, even after becoming the current president, Nobuo Naito, this feeling has continued to be connected.

The "three-way good" left by Omi merchants is a guideline for many managers, but we are aiming for "five-way good" management. It is based on the idea that "the greatest and highest mission and responsibility of corporate management is the pursuit and realization of the happiness of all people involved in the company."

To do this, we will do the following:

- Strengthening organizational strength by fostering human resources with a high sense of ownership,

- Q2 Behavioral thinking [time investment in the second area of 7 habits]

- Creating an organization with everyone's participation centered on the vision

With those values that we value, we will realize the vision of "improving the happiness of all employees" and "a company that will continue to evolve for over 100 years."

These are all mission-based.

Efforts for

human resource

development

Philosophy

- ojt (Internal training)

- off-jt (External training)

- Level-based training

- Purpose-specific training

- Skill-based training

- Self-directed learning / e-learning

Greeting

I believe that "manufacturing" is part of the service industry. Our service to our customers is one of the essential spirits to create reliable products and earn their satisfaction and trust. Nowadays, the needs of society are accelerating and changing every day. It is our proposition how we can share our wisdom in this trend and provide products that satisfy our valued customers as part of our "service". In addition, we believe that it is a certain condition of "manufacturing" to finish what the customer wants into a product without excess or deficiency. We will fully utilize the experience and achievements we have gained over many years to respond to complicated needs, and by accumulating what we have gained in this process, we will further satisfy and trust our customers in the future. I sincerely hope that it will bear fruit. To that end, all of our employees will work together to make continuous efforts for better "manufacturing." We look forward to your continued support and patronage.

COMPANY PROFILE

| Company name | Taisho Optical Co., Ltd. |

| Creation | 1973 - Showa 48 |

| Capital | 20 million yen |

| Representative | President and CEO Nobuo Naito |

| employees | 65 people |

| Business content | Manufacturing and sales of optical lenses Spherical lens, aspherical lens, prism, beam splitter, flat plate, optical junction, lens holder Other custom products / optical thin film manufacturing / sales Anti-reflection film (single layer AR / multi-AR) / dichroic coat / UV / IR cut / half mirror / laser mirror / cold mirror Bandpass filter, etc. |

HISTORY

2020年

12月

Website renewal

2020年

10月

New production management system started operation

2020年

10月

Regional future leader certification - Ministry of Economy, Trade and Industry

2020年

4月

Joint research with National Institute of Advanced Industrial Science and Technology Tsukuba Continued with new research content

2019年

11月

Business continuity strengthening plan certification - Ministry of Economy, Trade and Industry Kanto Economic Affairs Bureau

2019年

11月

Adopted manufacturing subsidy in 2018 "Sophistication of mind-taking process"

2019年

9月

Introduced transmission reflection eccentricity measuring instrument

2019年

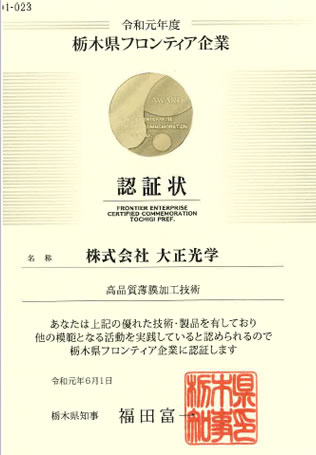

6月

Tochigi Prefecture Frontier Company Certification (Tochigi Prefecture)

2019年

4月

Started joint research with National Institute of Advanced Industrial Science and Technology, Tsukuba

2018年

10月

Introduced automatic blasting machine

Fuji S / S Pneum Blaster

2018年

7月

Approval of advanced equipment introduction plan (Kanuma City)

2018年

6月

Adopted manufacturing subsidy in 2017 "Transformation of business form for development and manufacturing of new functional thin films"

2018年

5月

Showa Vacuum Co., Ltd. Ultra-high performance optical thin film deposition equipment Sapio 1300 (Tochigi No. 2 Factory)

2018年

4月

Start of operation of medium-term management plan

2018年

3月

Established a new Corporate Planning Office due to organizational changes

2018年

3月

Introduced a new spectroscopic measuring device.

Hitachi UH4150 Spectrometer (Tochigi No. 2 Factory)

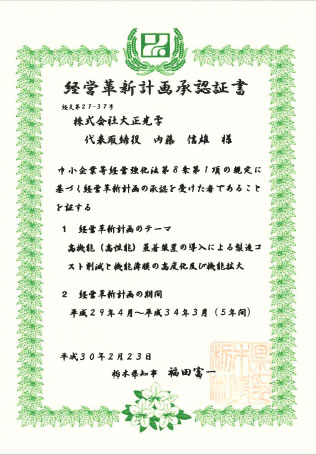

2018年

2月

Management Innovation Plan Certification (Tochigi Prefecture) "Reduction of manufacturing costs by introduction of high-performance thin-film deposition equipment and advancement of high-performance thin films and expansion of functions"

2018年

1月

Switched the air conditioner of the second factory to energy saving and completed the construction

2017年

12月

Introduced a new reflectance measuring instrument Olympus USPM-RU - Headquarters factory

2017年

8月

Adopted support subsidy to promote energy-saving investment "Introduction of energy-saving air conditioner to Tochigi No. 2 Factory"

2017年

2月

Management improvement plan certification(Ministry of Economy, Trade and Industry Kanto Bureau of Economy, Trade and Industry)

2016年

9月

Eco Action 21 certification / registration(Start of active efforts for environmental activities)

2015年

6月

Headquarters relocation (from Toda City, Saitama Prefecture to Kanuma City, Tochigi Prefecture)

2015年

4月

Homepage renewal

2014年

8月

Strengthen sales department (increase technical sales staff, expand ordered products)

2014年

6月

Adopted manufacturing subsidy in 2013

2013年

5月

Order / production management system update operation started

2012年

11月

Start of update operation of measuring device and spectrophotometer

2011年

7月

Introduced new cleaning equipment

2011年

3月

Addition of continuous vapor deposition equipment "CES950"

2010年

2月

Consolidate sales department to Tochigi factory

2008年

3月

Opened a sales office at the head office in Toda City, Saitama Prefecture

2007年

11月

Addition of continuous vapor deposition equipment "CES 950"

2007年

4月

Nobuo Naito became the representative director

2005年

6月

Introduced glass scriber

2004年

8月

Addition of continuous vapor deposition equipment "CES 950"

2004年

1月

Expansion of vapor deposition equipment "ACE 1350"

2001年

6月

Tochigi No. 2 Factory completed

1999年

12月

Introduced a high-precision automatic centering machine for small size only

1995年

11月

Saitama factory merged with Tochigi factory to expand Tochigi factory

1991年

10月

Tochigi factory court building completed

1990年

9月

Completion of Tochigi Factory centering Building

1989年

9月

Change from a limited company to a joint-stock company

1989年

5月

Integrated production of centering, vapor deposition and process is possible

1982年

8月

Introduced vacuum vapor deposition equipment to expand the range of production processes

1979年

5月

Reorganization

1977年

8月

Moved the factory to the current location and also supports the lens field for watches and electronic devices

For optical lenses, etc., start shifting to integrated process production

1973年

6月

The current chairman, Atsushi Naito, founded an optical lens processing business in Toshima-ku, Tokyo.